Industries & Clientele

Slurry Pumps

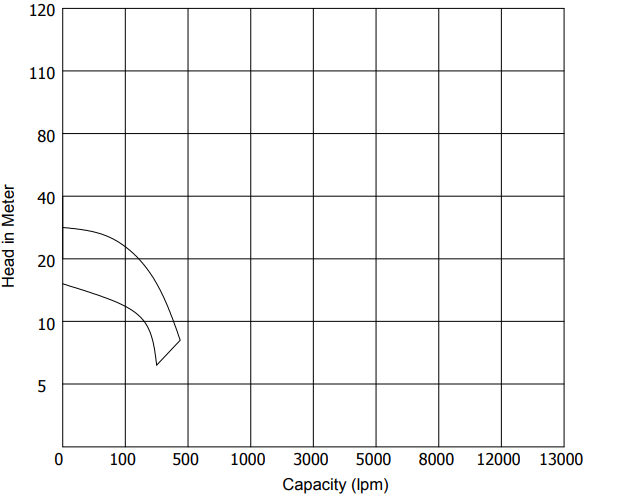

Dewatering Pumps

Nonclog & Waste Water Pumps

Clear & Raw Water Pumps

Stainless Steel Pumps

Hot Water Pumps