Stainless Steel Pumps

Pumping Sea water or any kind of corrosive liquids requires a very robust & reliable submersible pumps. For such critical applications, it’s just not enough for product to be robust in design, but it is equally important to have a high reliability material which can serve well in these applications in long run. Darling Pumps over last 20 years has a proven track record for handling Sea water & other corrosive liquids, for this we have provided pumps in various grades of SS & Duplex SS. These Pumps ideal for Pumping Sea Water, corrosive liquids & liquids with Lower pH, Desalination Projects, Reverse Osmosis, Pumping Effluents, Wastes, and Slurries with lower pH, Chemical Handling Plants & many more similar applications.

Stainless Steel Pumps

Features

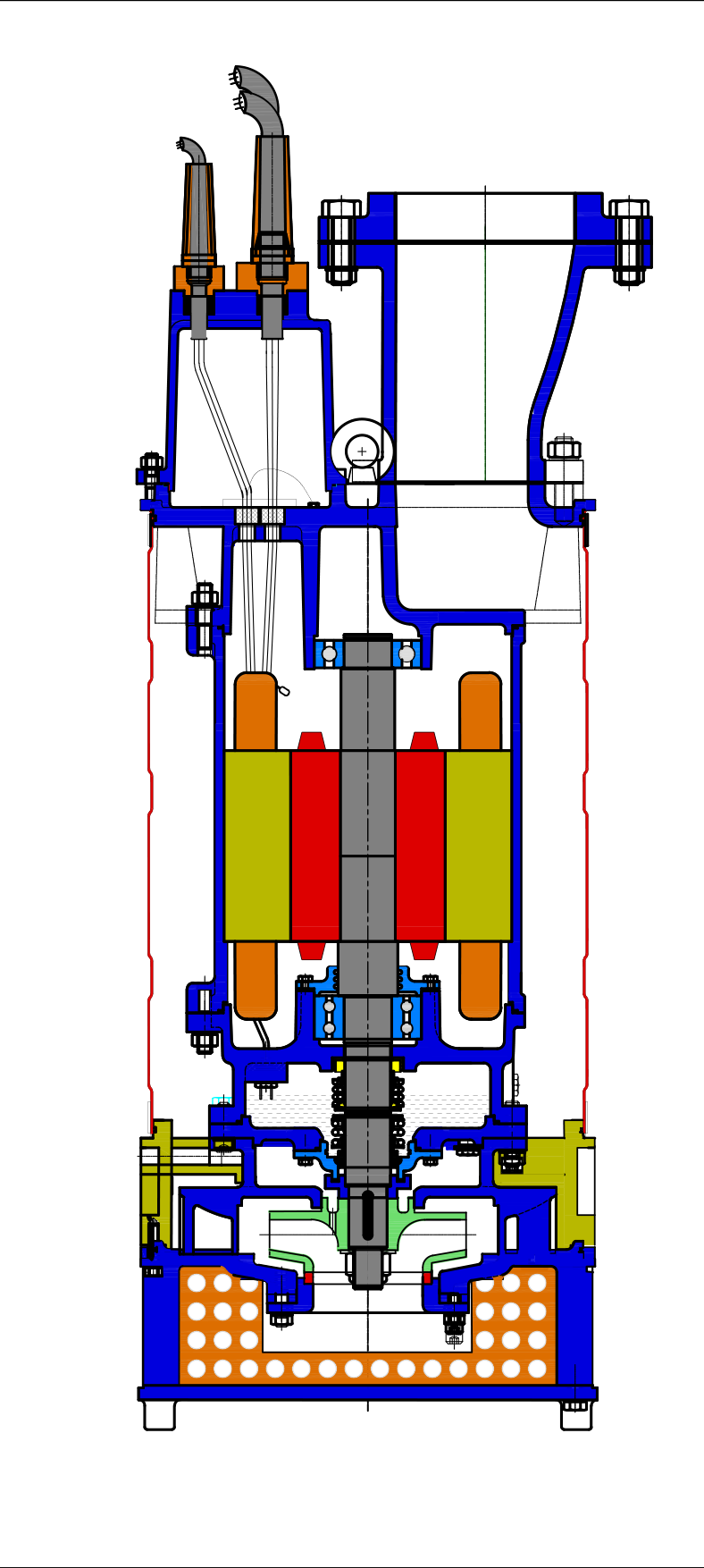

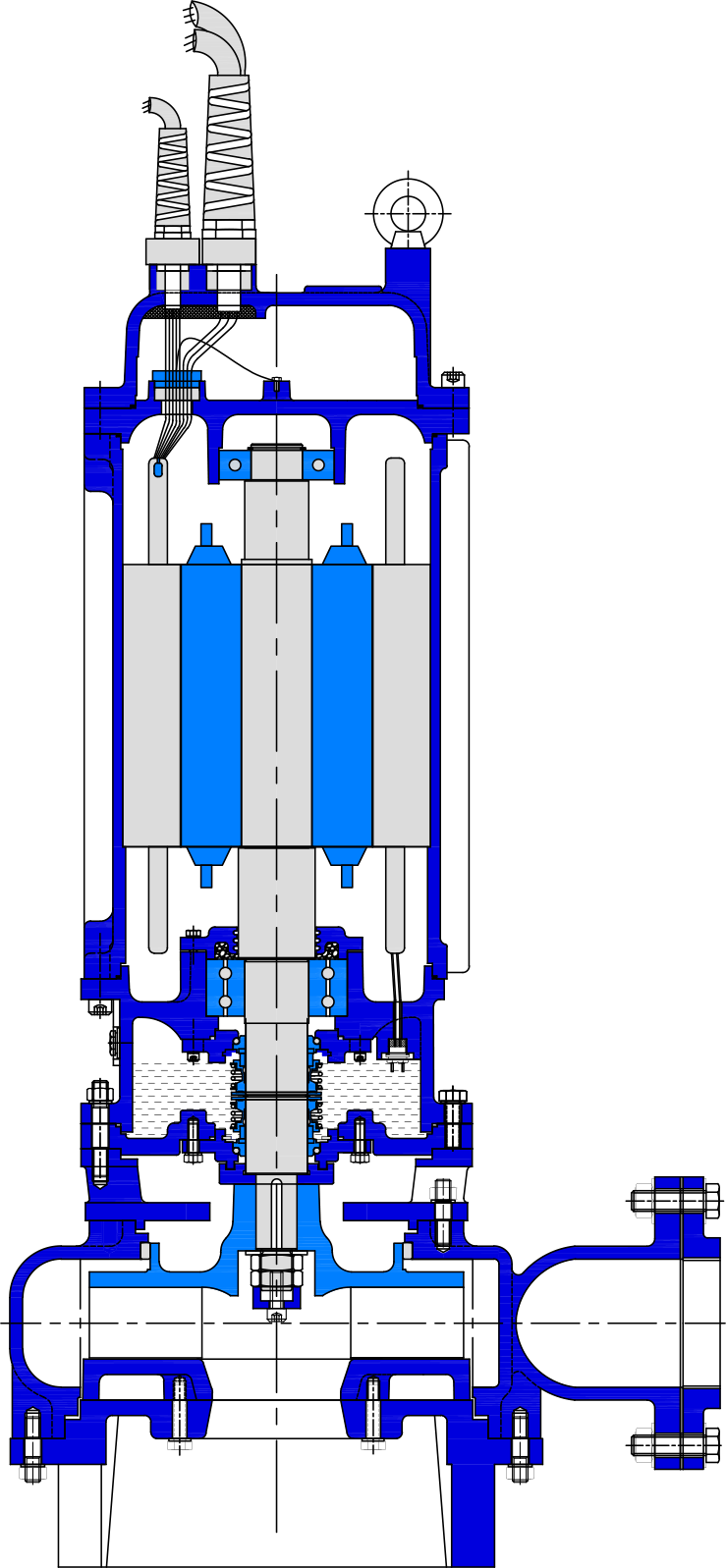

| Impeller – Special corrossion / errossion resistant impellers to suit specifc applications. Impeller to suit Solids passage up to 100mm. |

| Motor – Highly efficient dry motor with built -in protection against temperature rise. Motor capable to withstand wide voltage fluctuations. |

| Shaft – Extra heavy duty SS Shaft. |

| Mechanical Seals – Specially designed Dual Mechanical seals with unique rubber material are fitted in independent seal chambers. Design is such that Seals are not exposed to pumpage liquid and are also independent of discharge pressure. |

| Bearing– Heavy duty ball bearing used at top and bottom ends to balance adverse load. |

| Cable Sealing – Special leak proof cable sealing arrangement,to avoid ingress of water through cable.no need to open motor for changing cable. |

Applications

- Pumping Sea Water

- Pumping Aggressive liquids & liquids with high pH

- Desalination Projects

- Projects for River Osmosis

- Pumping Effulents, Wastes, Slurries with high pH

- Chemical Handling Plants & Many More….

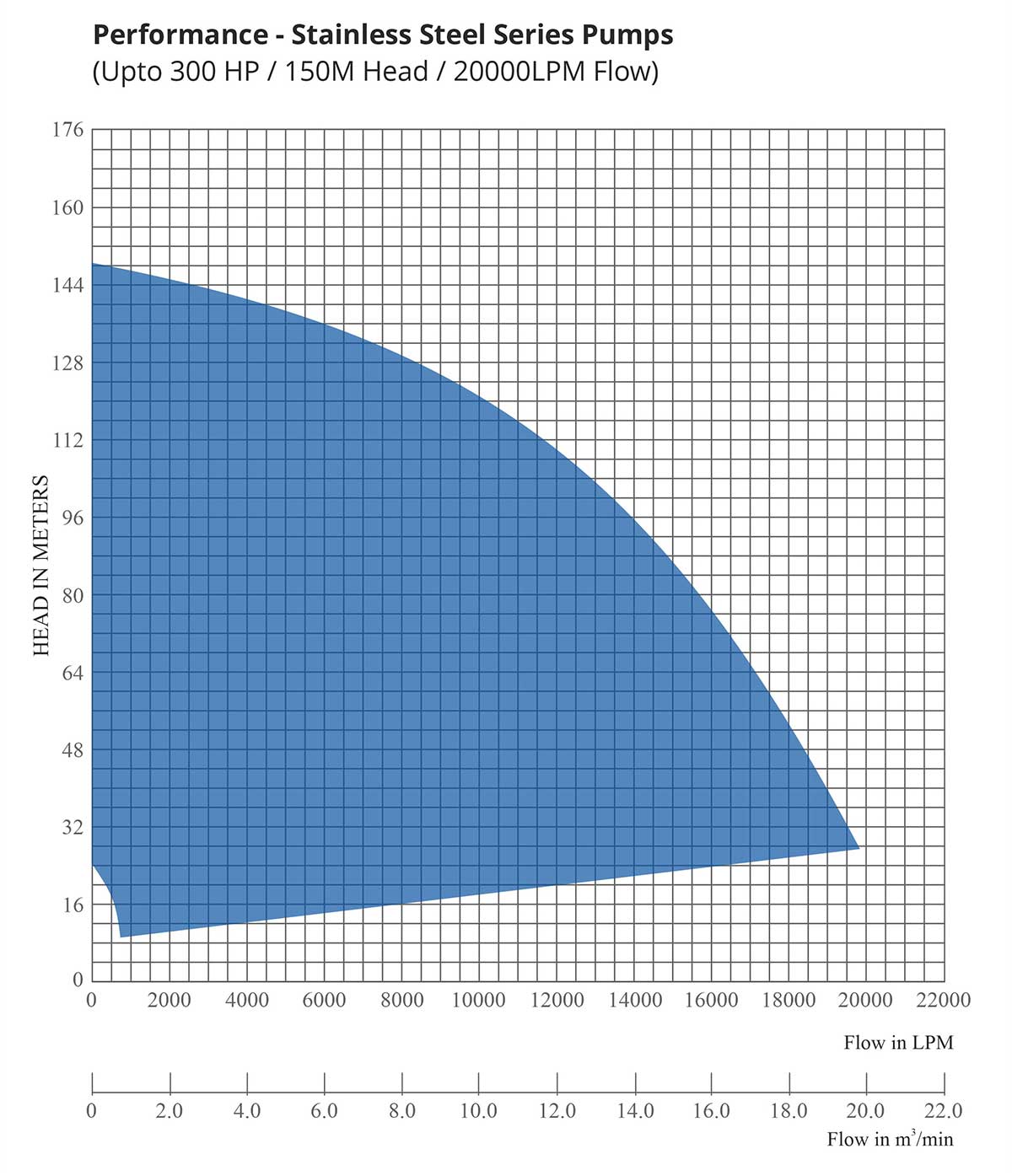

Stainless Steel Pumps

| Tech. Specifications* | ||

| Rating | : | Up to 300 HP |

| RPM | : | 2900 / 1450 / 960 |

| Frequency | : | 50 HZ |

| Supply | : | Three phase- 415 V |

| Starting | : | DOL / STAR DELTA |

| Motor | : | Wet type / Dry type |

| Process Data | ||

| Liquid temperature | : | Max 40° C |

| Liquid Density | : | Max 1100 kg/m3 |

| Suitable for liquid pH | : | 2 ≤ |

| Stainer Hole Size | : | Up to 100 mm |

| Materials* | ||

| Impeller | : | Various grades of SS & Duplex |

| Shaft | : | Various grades of SS & Duplex |

| Difusser | : | Various grades of SS & Duplex |

| Wear plate | : | Various grades of SS & Duplex |

| Mech. Seal | Sic v/s Sic, Tc v/s Tc with special rubber material | |

Stainless Steel Pumps

Options

- Pumps can be provided in various grades of SS, Alloy 20, Haste Alloy, Duplex, Super Duplex

- Option of pumps for Clear Water Pumping, Waste Water, Effulents & Slurries with solid passgaes up to 100 mm

- Pumps can be offerred for specific gravity up to 2.8

- Pumps can be offered for 60 Hz.

- Pumps can be offerred with pontoon arrangement as well

- Guiderail / Fastout arrangement Upto 20 mtr pit depth.

Recommendations

- Always flush the pump with clean water after use.

- In case of maintenance always use genuine spares.

- Ensure use of proper control panel for proper safety & running of pumps.

- Always ensure that pump is properly earth.