Non Clog and Waste Water Pumps

Today, water treatment, its conservation, recycling & its reuse has assumed a greater significance. Thus, the demand for pumping / treating waste water is going up steadily. The present methods are also more versatile & thus demand greater reliability as far as pumping needs are concerned. Darling Pumps having worked effectively in this sector can offer reliable & effective pumping solution.

As we have been working in this sector for over 4 decades, we have made our pump designs more adaptable to challenges in this sector… not only in terms of capacities but also in terms of MOC’s & many significant add-on features.

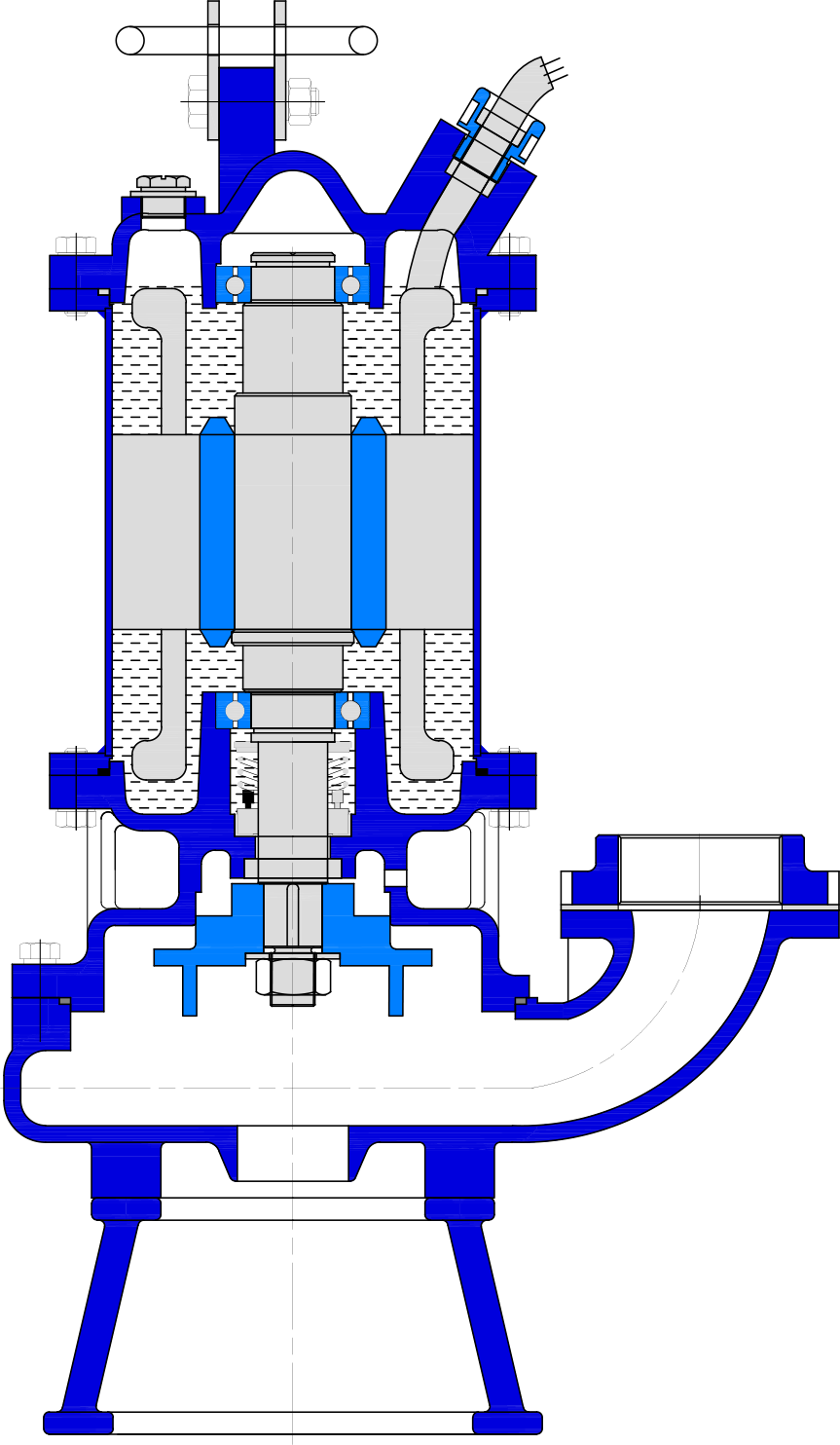

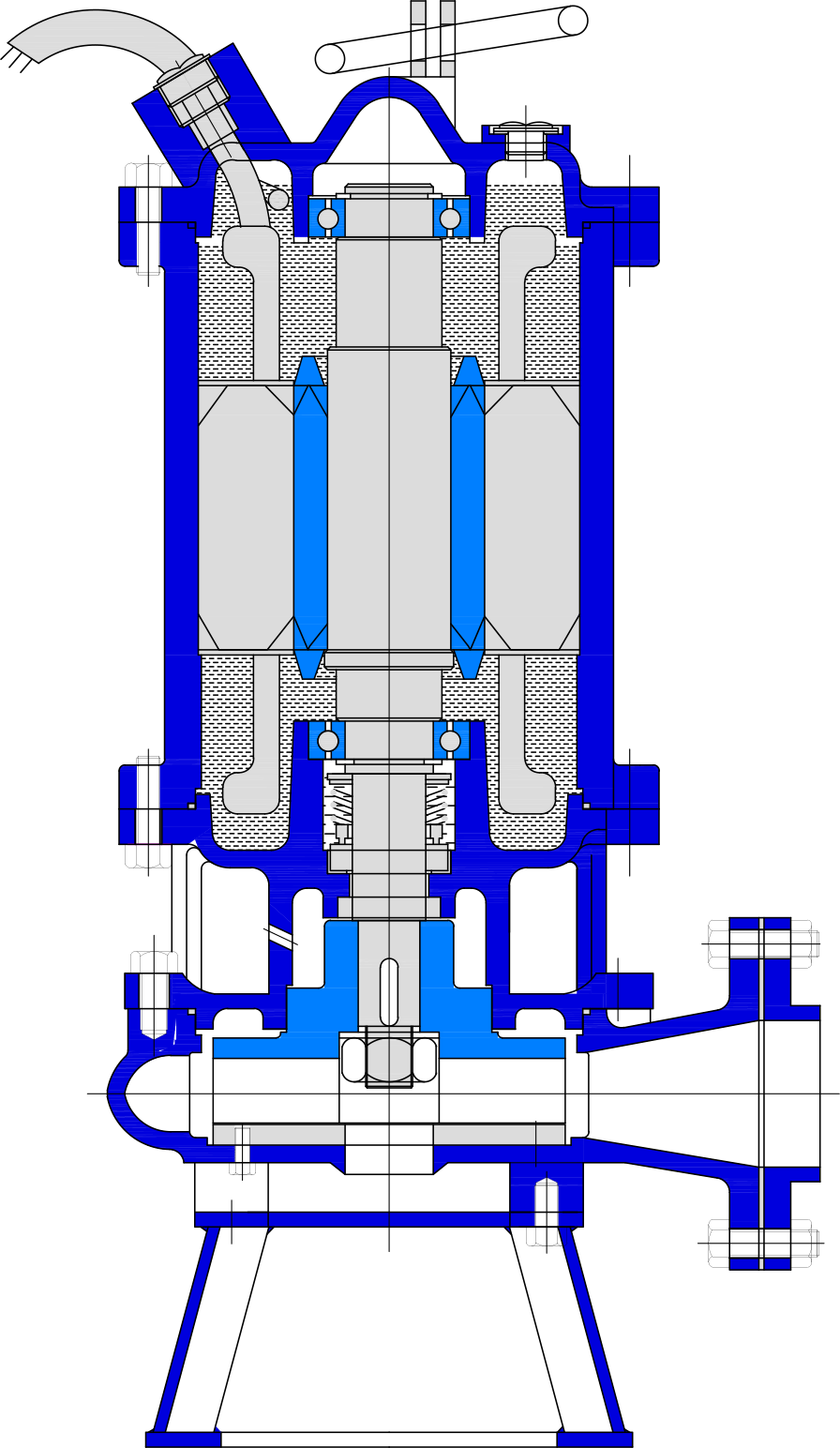

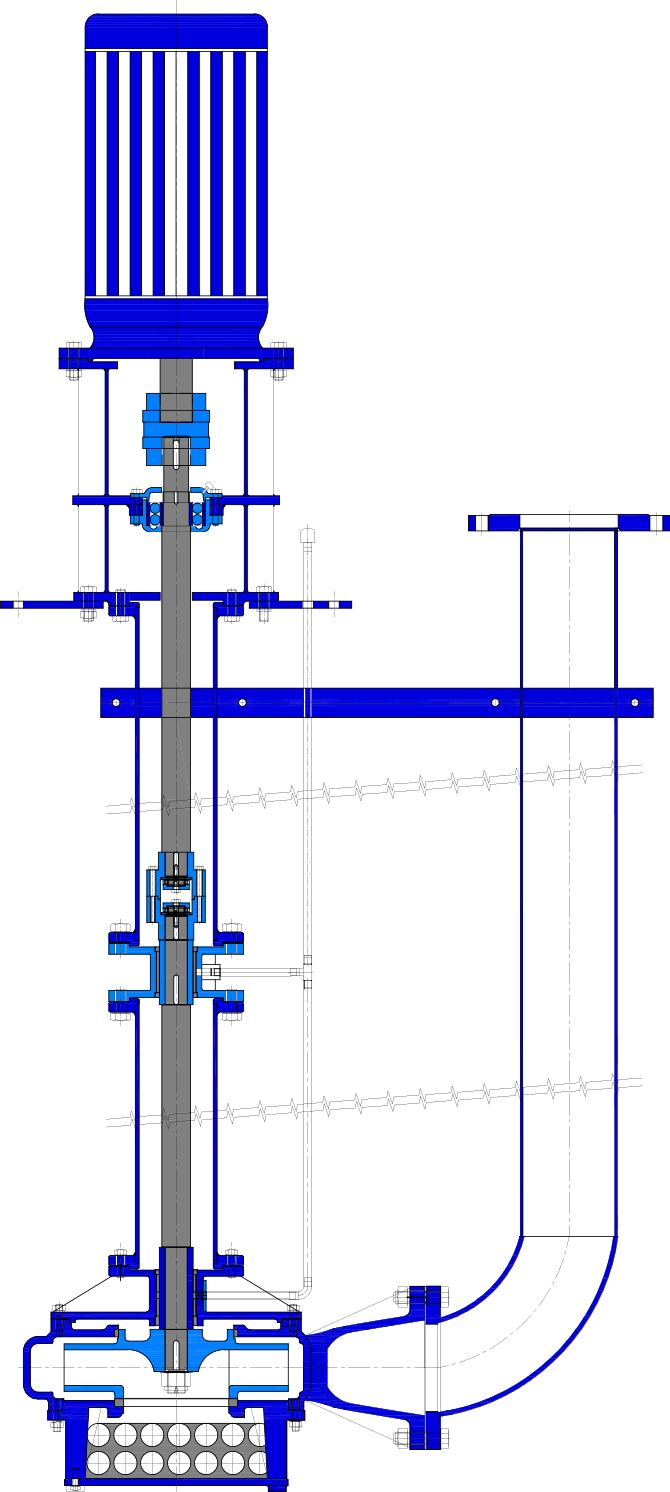

Non-clog Series Pumps

Features

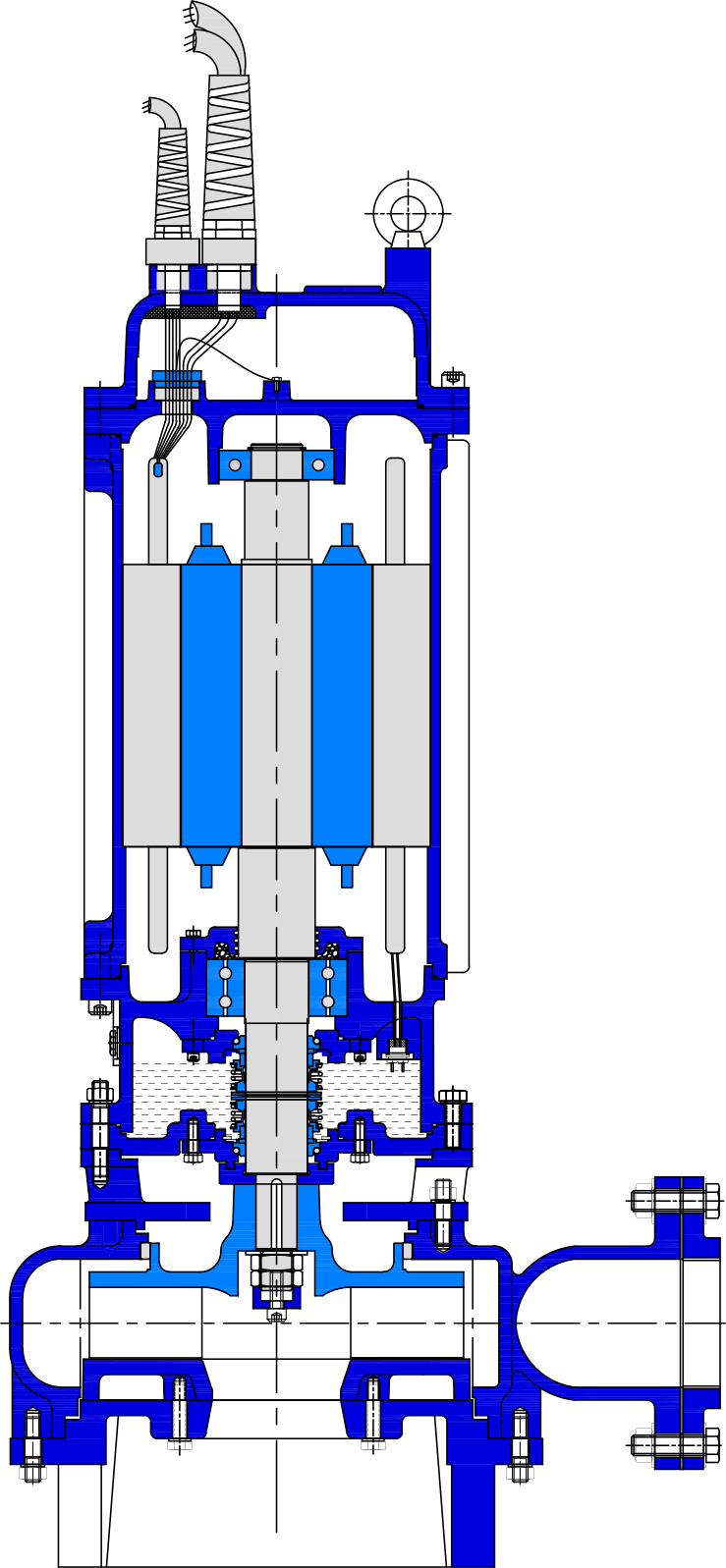

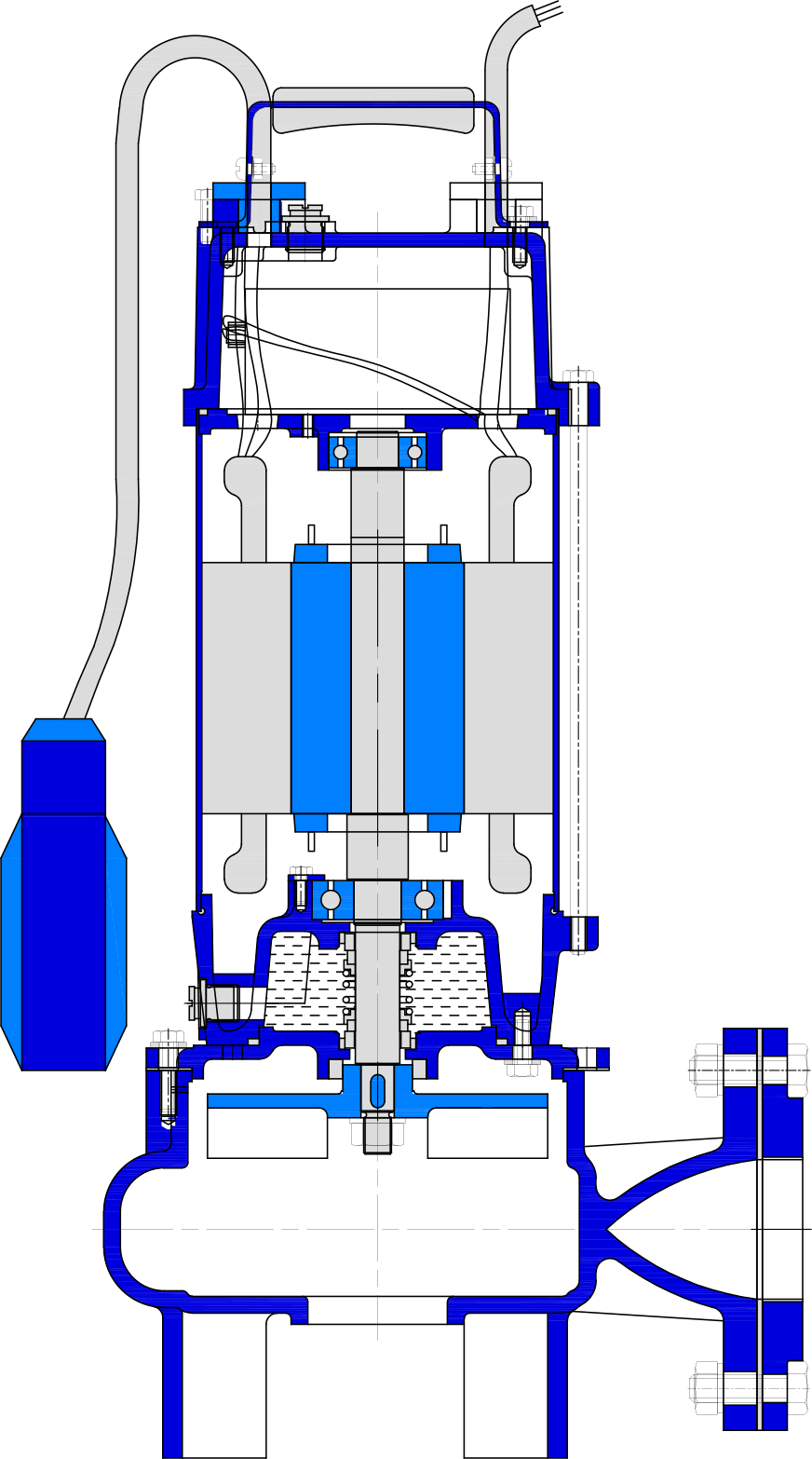

| Impeller -Wear resistant SS impeller with wide passages that can pass solids up to 100mm. |

| Motor – Highly efficient dry motor with built -in protection against temperature rise.motor capable to withstand wide voltage fluctuations. |

| Shaft – Extra heavy duty SS Shaft. |

| Mechanical Seals -Dual Mechanical seal fitted in independent chambers, not exposed to pumpage liquid and devoide of discharge pressure. |

| Bearing– Heavy duty ball bearing used at top and bottom ends to balance adverse load. |

| Seal Guard Protection-Additional protection for machanical seal by seal guard. |

| Cable Sealing – Special leak proof cable sealing arrangement,to avoid ingress of water through cable.no need to open motor for changing cable. |

| Treashguard -Special arrangement to avoid builtup of solids above the impeller. |

Applications

- Municipal Waste, Raw & Un-Screened Sewage

- Industrial Wastes & Effluents

- Pharmaceutical, Textile & Tanning Plants

- Municipal Sewer pumps

- Effluent Treatment And Sewage Treatment Plants

- Ro Reject / Desalination Projects

- Chemical Handling Plants & Many More….

- Private Pumping / Sewage Stations.

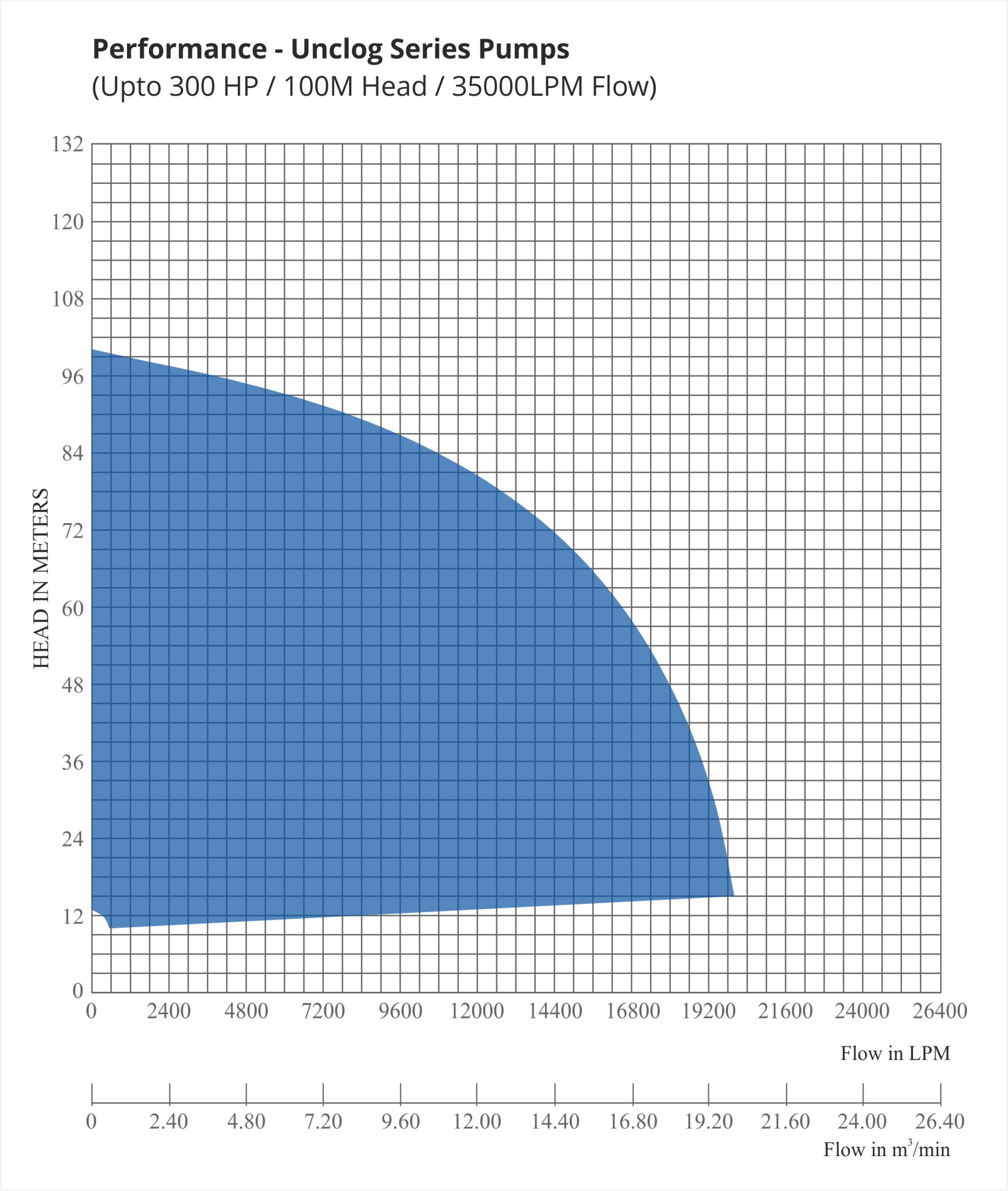

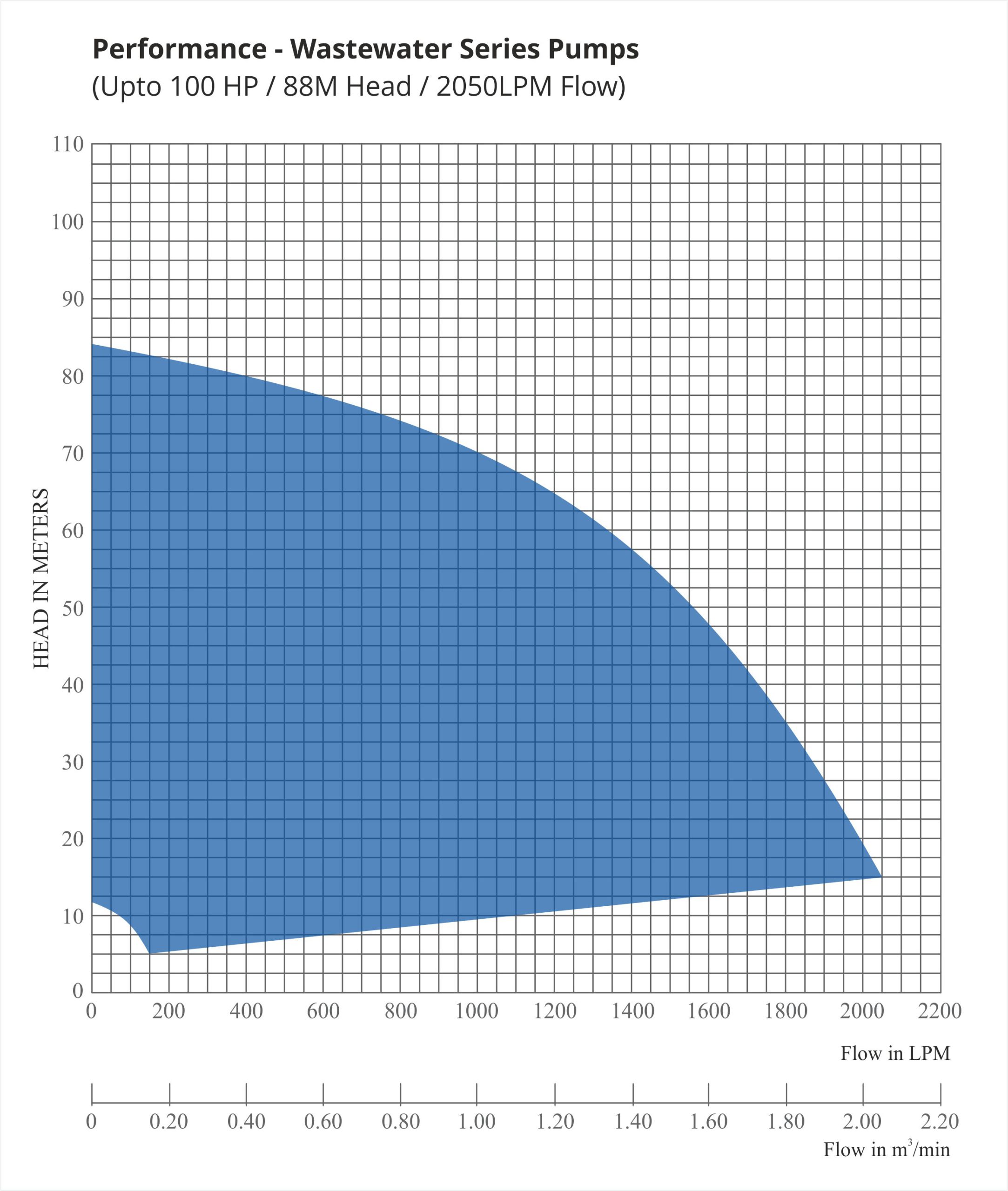

Non-clog Series Pumps

| Tech. Specifications* | ||

| Rating | : | Up to 300 HP |

| RPM | : | 1450 /960 |

| Frequency | : | 50 HZ |

| Supply | : | Three phase- 415 V |

| Starting | : | DOL |

| Motor | : | Wet type / Dry type |

| Process Data | ||

| Liquid temperature | : | Max 40° C |

| Liquid Density | : | Max 1100 kg/m3 |

| Suitable for liquid pH | : | 6 to 8 |

| Stainer Hole Size | : | Up to 100 mm |

| Materials* | ||

| Impeller | : | CA – 15, CF8, CF8M,various grades of Cl |

| Shaft | : | AISI-410, SS-304, SS-316 |

| Difusser | : | Various grades of CI/ SS |

| Wear plate | : | Various grades of CI/ SS |

| Mech. Seal | Sic v/s Sic, Tc v/s Tc | |

Non-clog Series Pumps

| Pump Model | HP/KW | RPM | OUTLET / DN SIZE | SOLID PASSAGE | MINIMUM SUBMERGENCE (Approx.) | WIDTH / OUTER DIA (Approx.) | HEIGHT (Approx.) | Net Weight (In Kg) (Approx.) |

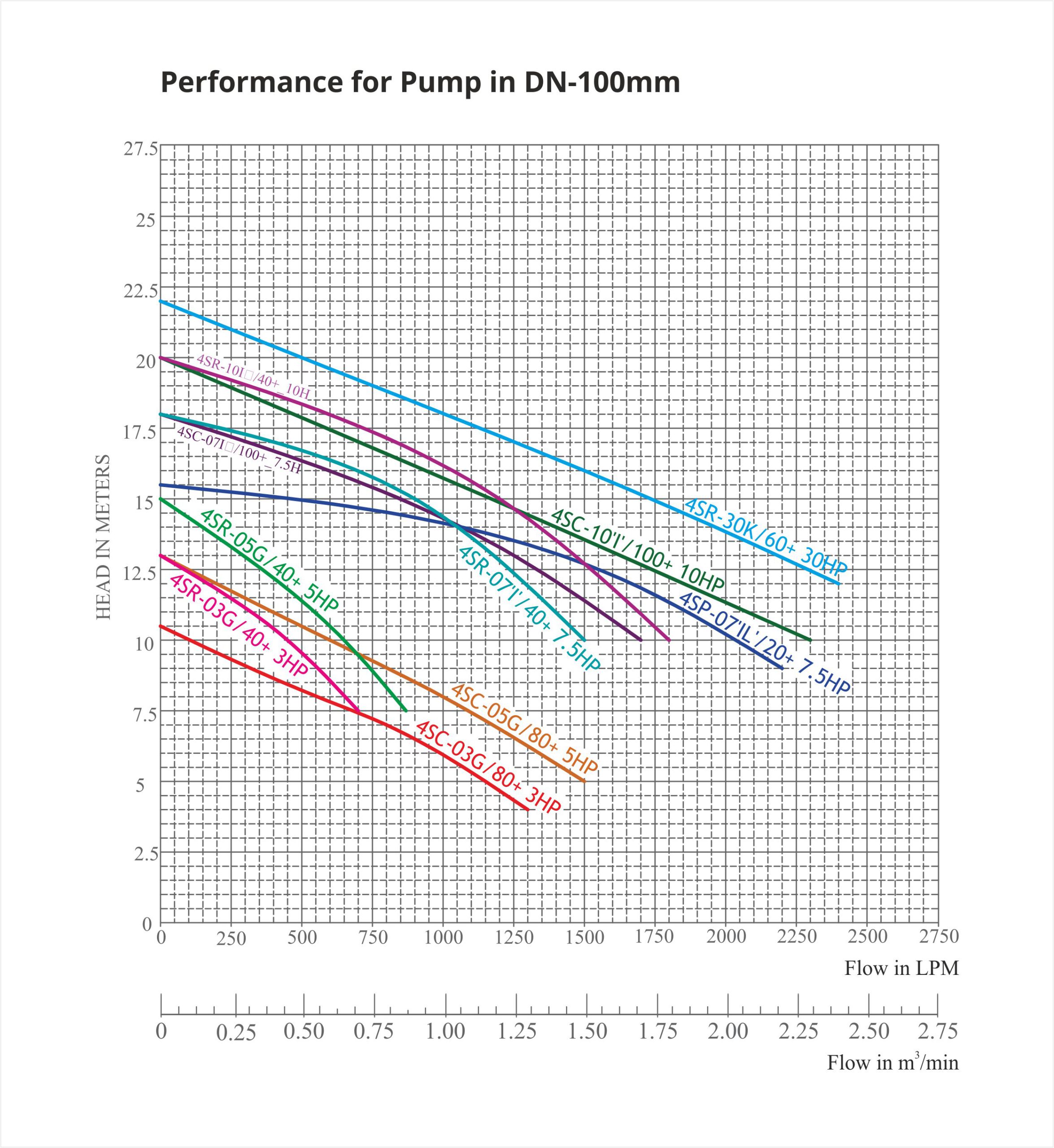

| 4SR-03G/40+ | 3.0/2.2 | 1440 | 100 | 40 | 720 | 405 | 875 | 125 |

| 4SC-03G/80+ | 3.0/2.2 | 1440 | 100 | 80 | 720 | 405 | 875 | 125 |

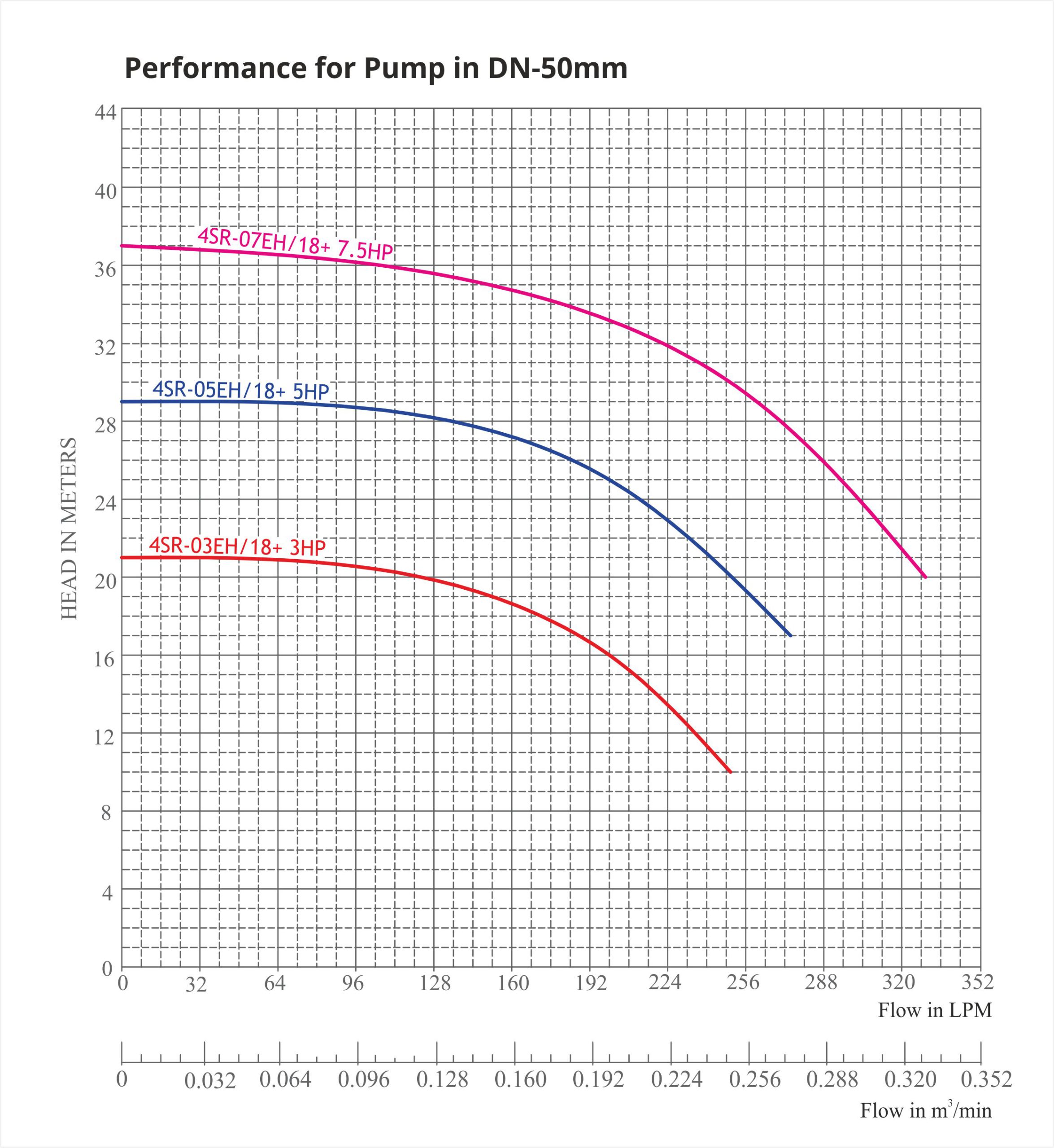

| 4SR-03EH/18+ | 3.0/2.2 | 1440 | 50 | 18 | 600 | 460 | 750 | 115 |

| 4SR-05EH/18+ | 5.0/3.7 | 1440 | 50 | 18 | 600 | 460 | 750 | 120 |

| 4SR-05G/40+ | 5.0/3.7 | 1440 | 100 | 40 | 720 | 405 | 875 | 130 |

| 4SC-05G/80+ | 5.0/3.7 | 1440 | 100 | 80 | 720 | 405 | 875 | 130 |

| 4SR-07EH/18+ | 7.5/5.5 | 1450 | 50 | 18 | 600 | 460 | 800 | 180 |

| 4SR-07I/40+ | 7.5/5.5 | 1450 | 100 | 40 | 760 | 465 | 955 | 205 |

| 4SC-07I/100+ | 7.5/5.5 | 1450 | 100 | 100 | 760 | 465 | 955 | 205 |

| 4SP-07IL/20+ | 7.5/5.5 | 1450 | 100 | 20 | 690 | 480 | 890 | 177 |

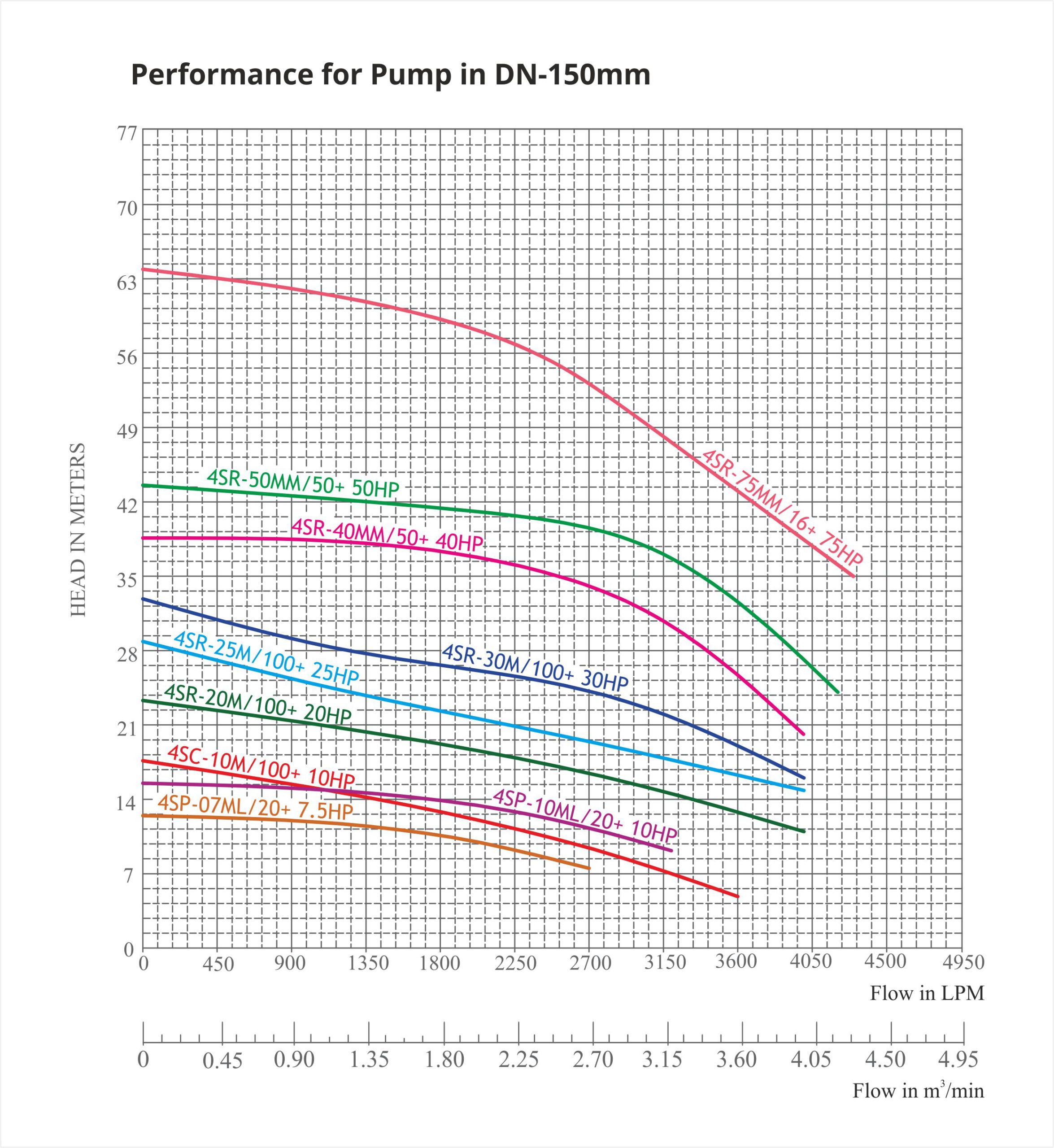

| 4SP-07ML/20+ | 7.5/5.5 | 1450 | 150 | 20 | 690 | 520 | 895 | 187 |

| 4SP-10ML/20+ | 10/7.5 | 1450 | 150 | 20 | 690 | 520 | 895 | 197 |

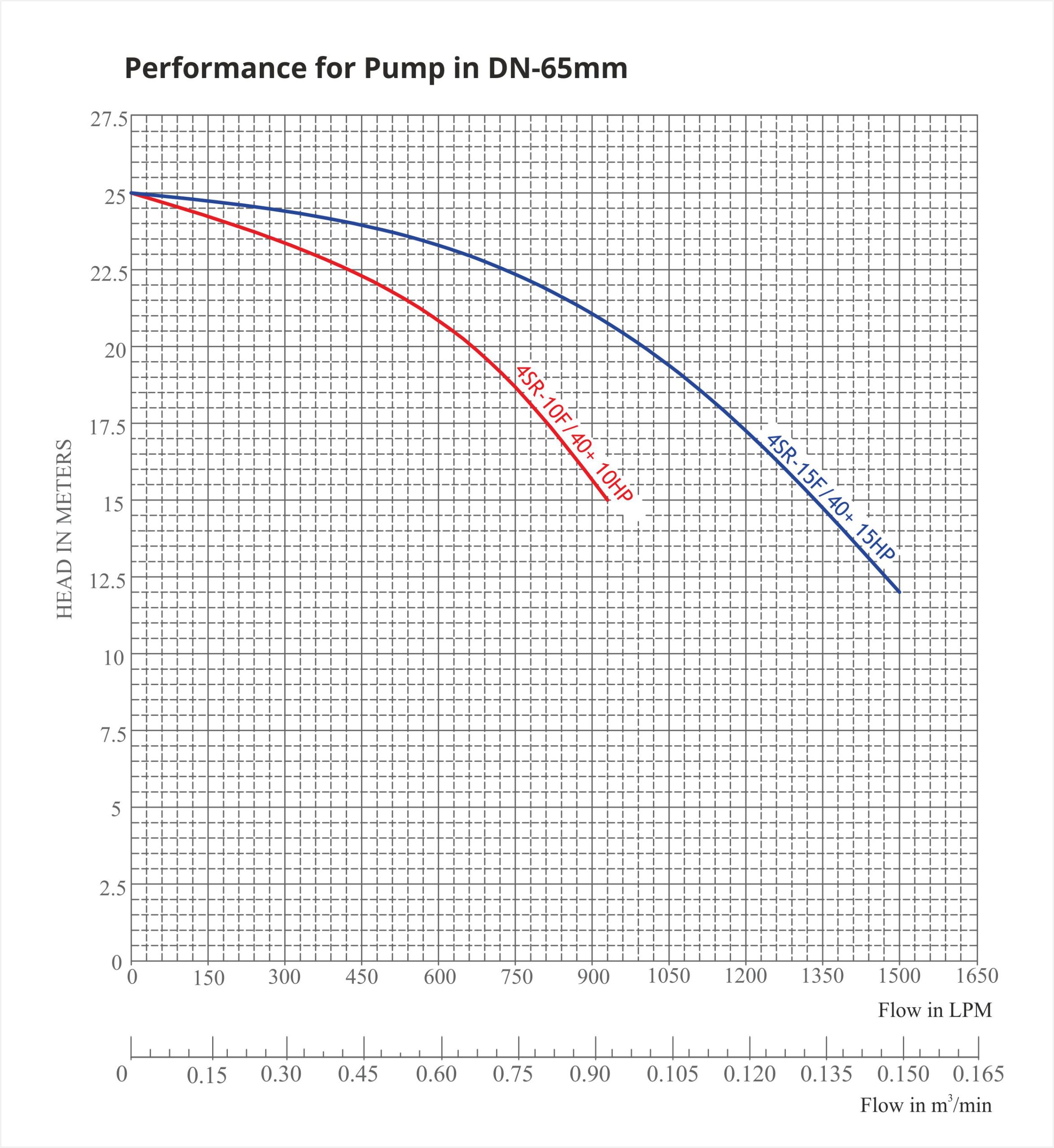

| 4SR-10F/40+ | 10/7.5 | 1450 | 65 | 40 | 610 | 480 | 810 | 137 |

| 4SR-10I/40+ | 10/7.5 | 1450 | 100 | 40 | 760 | 465 | 955 | 242 |

| 4SC-10I/100+ | 10/7.5 | 1450 | 100 | 100 | 760 | 465 | 955 | 242 |

| 4SC-10M/100+ | 10/7.5 | 1450 | 150 | 100 | 740 | 590 | 945 | 242 |

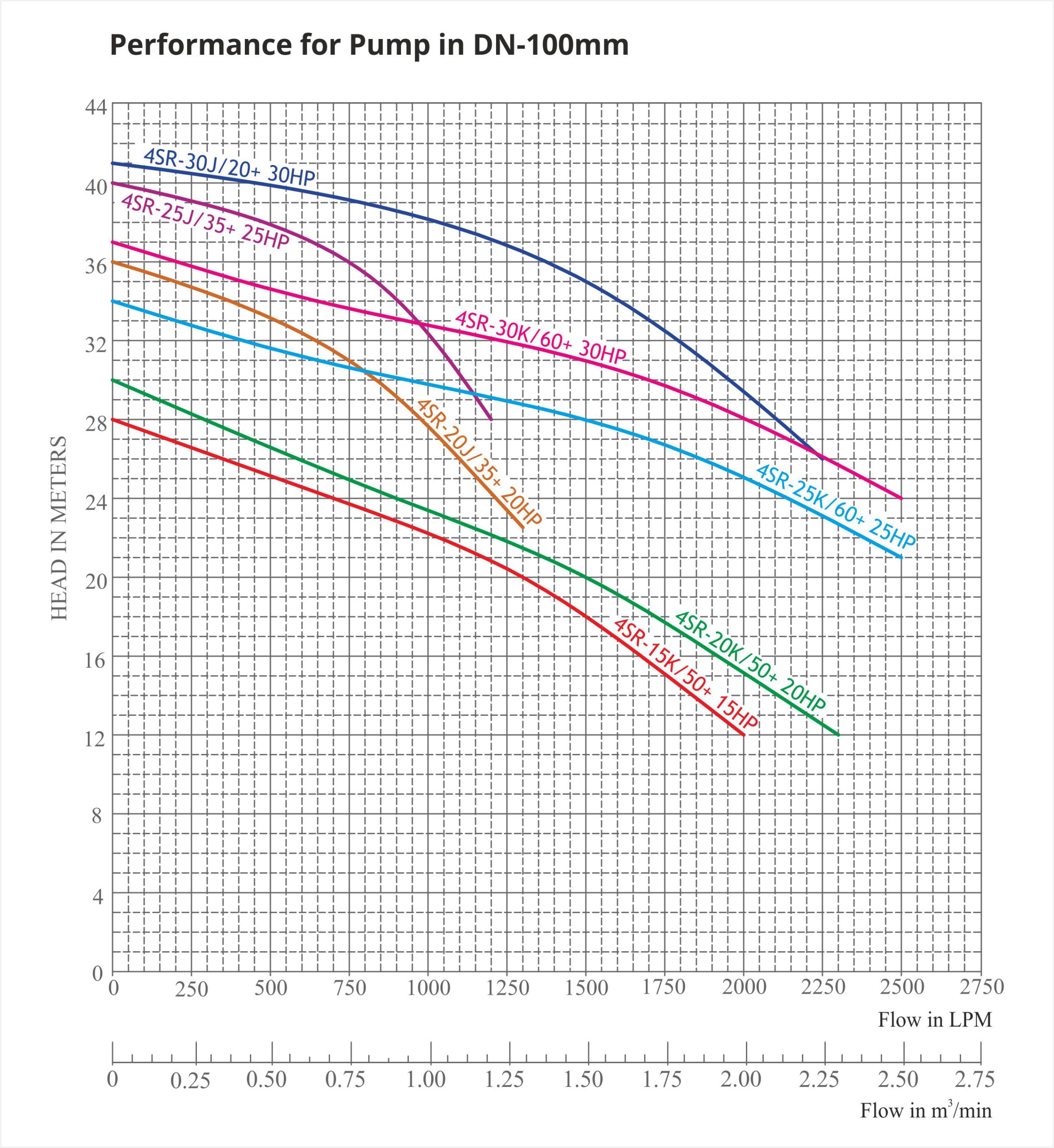

| 4SR-15K/50+ | 15/11 | 1450 | 100 | 50 | 780 | 580 | 990 | 267 |

| 4SC-15I/100+ | 15/11 | 1450 | 100 | 100 | 820 | 465 | 1025 | 267 |

| 4SR-15F/40+ | 15/11 | 1450 | 65 | 40 | 675 | 480 | 880 | 220 |

| 4SR-20K/50+ | 20/15 | 1460 | 100 | 50 | 860 | 580 | 1065 | 292 |

| 4SR-20J/35+ | 20/15 | 1460 | 100 | 35 | 850 | 635 | 1055 | 267 |

| 4SR-20M/100+ | 20/15 | 1460 | 150 | 100 | 870 | 590 | 1080 | 295 |

| 4SR-25J/35+ | 25/18.5 | 1460 | 100 | 35 | 850 | 635 | 1055 | 295 |

| 4SR-25K/60+ | 25/18.5 | 1460 | 100 | 60 | 870 | 580 | 1075 | 295 |

| 4SR-25M/100+ | 25/18.5 | 1460 | 150 | 100 | 870 | 590 | 1080 | 295 |

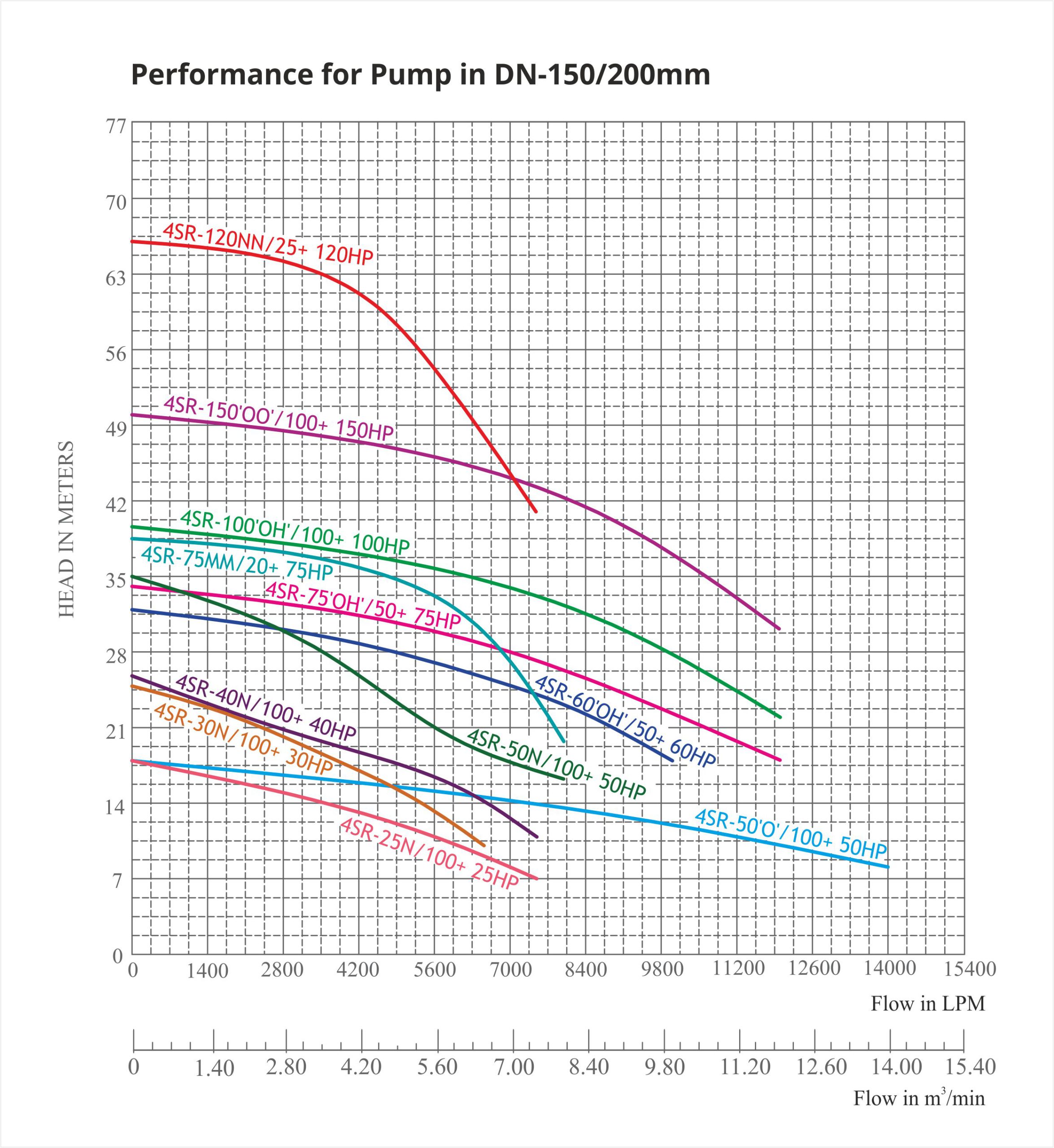

| 4SR-25N/100+ | 25/18.5 | 1460 | 200 | 100 | 910 | 670 | 1120 | 295 |

| 4SR-30J/20+ | 30/22 | 1460 | 100 | 20 | 935 | 635 | 1140 | 320 |

| 4SR-30K/60+ | 30/22 | 1460 | 100 | 60 | 955 | 580 | 1160 | 320 |

| 4SR-30M/100+ | 30/22 | 1460 | 150 | 100 | 960 | 590 | 1165 | 320 |

| 4SR-30N/100+ | 30/22 | 1460 | 200 | 100 | 1000 | 670 | 1205 | 330 |

| 4SR-40N/100+ | 40/30 | 1460 | 200 | 100 | 1000 | 670 | 1205 | 410 |

| 4SR-40M/50+ | 40/30 | 1460 | 150 | 50 | 870 | 730 | 1075 | 400 |

| 4SR-50M/50+ | 50/37 | 1460 | 150 | 50 | 990 | 730 | 1375 | 658 |

| 4SR-50N/100+ | 50/37 | 1460 | 200 | 100 | 1015 | 670 | 1505 | 510 |

| 4SR-50’O’/100+ | 50/37 | 1460 | 200 | 100 | 1230 | 780 | 1615 | 510 |

| 4SR-60’OH’/50+ | 60/45 | 1460 | 200 | 50 | 1225 | 785 | 1615 | 590 |

| 4SR-75’OH’/50+ | 75/55 | 1460 | 200 | 50 | 1225 | 785 | 1615 | 590 |

| 4SR-75MM/16+ | 75/55 | 1460 | 150 | 16 | 1175 | 760 | 1565 | 650 |

| 4SR-75MM/20+ | 75/55 | 1460 | 150 | 20 | 990 | 710 | 1395 | 700 |

| 4SR-100’OH’/100+ | 100/75 | 1460 | 200 | 100 | 1280 | 875 | 1700 | 900 |

| 4SR-120NN/25+ | 120/90 | 1460 | 200 | 25 | 1400 | 820 | 1815 | 850 |

| 4SR-150’OO’/100+ | 150/110 | 1460 | 200 | 100 | 1430 | 875 | 1850 | 1100 |

| Note: All dimensions are in millimeter (mm). | ||||||||

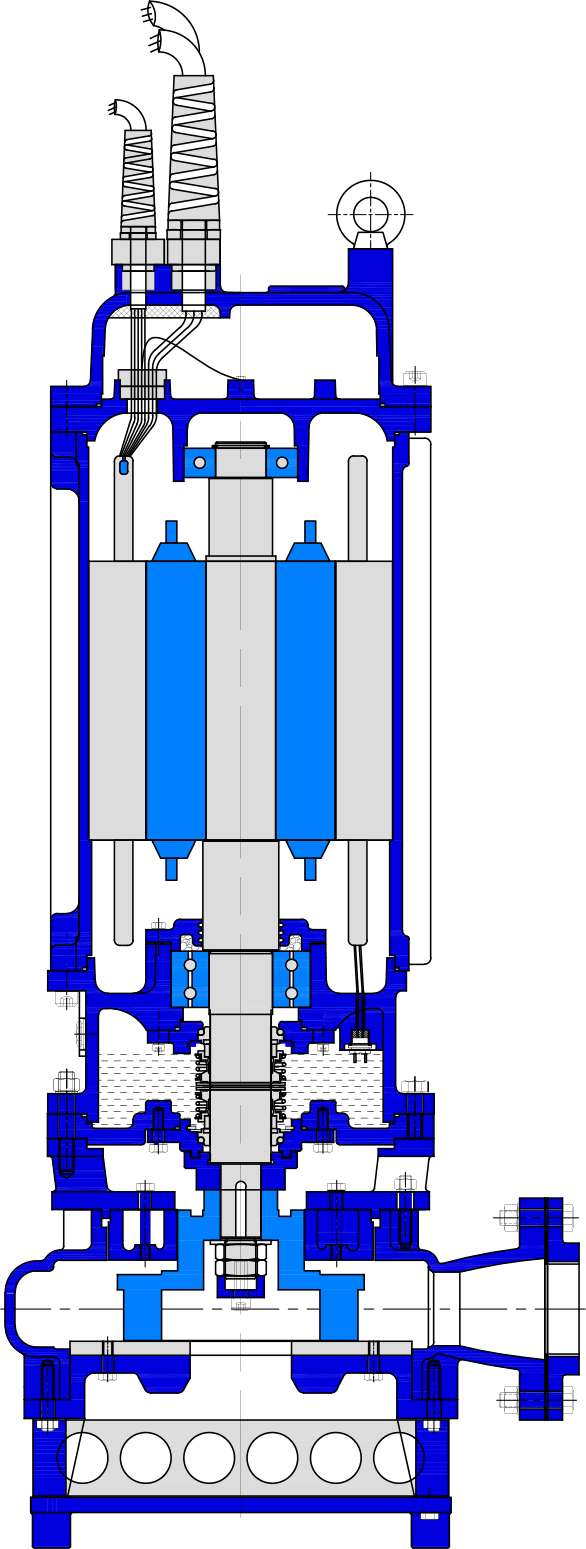

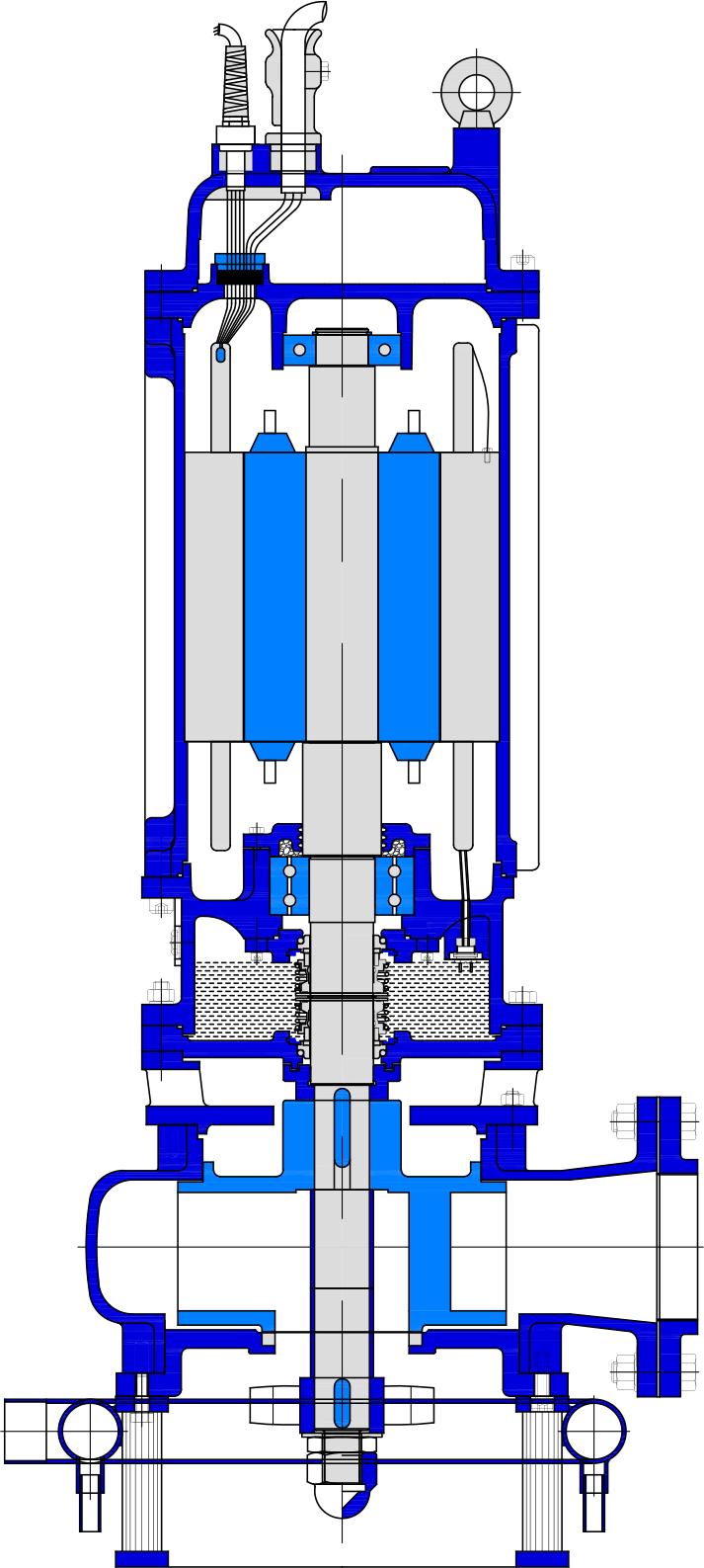

Non-clog Series Pumps

Options

- Option of pump with dry motor as well as oil filled motor.

- Option of pumps with inbuilt agitator arrangement.

- Pumps can be offered for 60 Hz.

- Option of pumps with cooling jacket.

- Option of pumps with Spiral cutting plate.

- Guiderail / Fastout arrangement Upto 20 mtr pit depth.

- Veriety of MOCs to choose from.

Recommendations

- Always flush the pump with clean water after use.

- In case of maintenance always use genuine spares.

- Ensure use of proper control panel for proper safety & running of dewatering pumps.

- Always ensure that pump is properly earth.